We design and build molds for plastics.

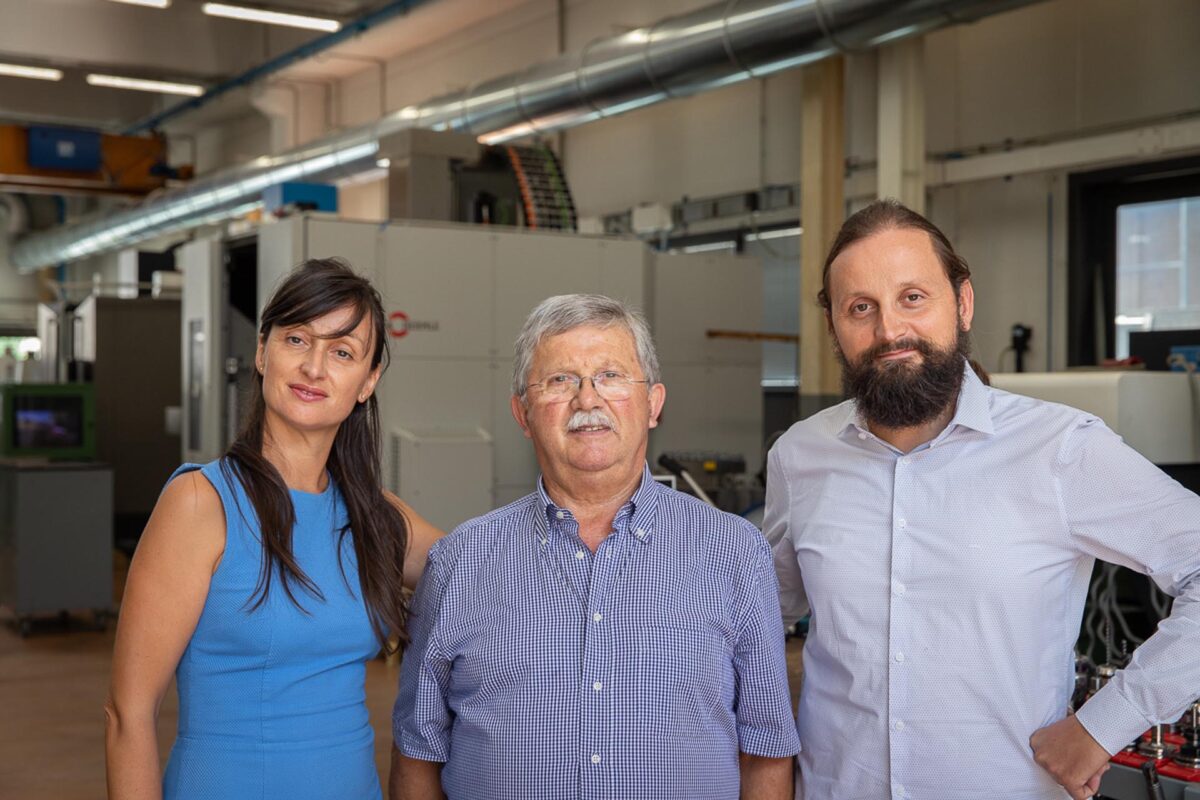

Today the company is managed by the second generation of entrepreneurs, supported by a highly specialized team of collaborators.

We are a young company, which has about 15 people around under 40y/o on average, with a very low turnover.

From the experience of Mario Rigon, father of the current administrators, the precious specific know-how of the workshop has been built, which in the hands of the young management is enriched with a profound competence in the most advanced, with an openness towards innovation in everything relating to the sector to which it belongs.

The founder’s imprint remains vital and there is a family atmosphere in the company. Management is still informal, human relationships are important: priority is given to the possibility of reconciling work and personal needs, results and satisfactions are shared, collaborating towards the best outcome of each project.

The internal specializations are divided into CAM design and programming, by the technical office, production, by the workshop workers, and administration.

One works with passion, giving one’s best,

and every testing becomes a moment to celebrate.

An entrepreneurial history since 1988

Rigon’s is a story of a lot of drive, imagination and a lot of commitment, which begins with Mario’s passion for his work.

The entrepreneurial spirit caused the company’s size and number of employees to grow until the year 2000, when the new Rigon srl headquarters were inaugurated in the current building on Via Artigianato in Povolaro di Dueville.

Growth is based on continuous innovation, bold investment and the centrality of people in every choice that is made.

Responsibility for the business passed to son Stephen in 2010, and in 2018 daughter Elena also joined the company.

With the same reliability and renewed passion, today we face each new challenge with optimism and walk toward a future that is always mindful of all stakeholders.

At the threshold of 40, after 23 years as an employee, Mario invests all his severance pay to start his own business.

It was a world of workmanship done by machines and man together, where the value lay in manual skill and success was decreed by inventiveness. Each mold was born as a unique piece, the result of experience and creativity, new solutions devised each time by human ingenuity.

The company’s growth stages are those typical of small entrepreneurship in northeastern Italy: from a sole proprietor to a family business with 5 employees, until the transition in 2000 to a more structured SRL, with a doubling of the size of the production facility, to which it moved in the following year.

The company’s trustworthiness is consolidated and grows, strengthened day by day by the honesty, integrity in business and utmost dedication of those at its helm.